EMC Measurements

This application note highlights the successful deployment of RF over Fiber technology for EMC testing of aircraft during development and qualification. Using RFoF technology is essential to achieve isolation in high-power radiated EMC tests and to test at very high frequencies up to 18GHz as standards require. This method enables to transmit the measurement signals over a substantial distance, exceeding 400 feet, to reduce the damage risk from the induced powerful test fields to the test equipment and personnel. This is typically achieved by housing the test equipment such as RF sweeper, network analyzer, and spectrum analyzer in a van or a fixed shelter. Several type of tests are possible including susceptibility of onboard equipment to lightning and other high energy radiation, interference with onboard communication, resonances in aircraft structure or cabling that could lead to arcs and damage and more. A case study with a leading aircraft builder demonstrated the effectiveness and reliability of this approach. Overall, this technology enhances the safety and resilience of aircraft design.

WHY RFoF INSTEAD OF COAX FOR EMC MEASUREMENTS?

Using RF over Fiber instead of coaxial cables for EMC testing in aircraft development presents several technical advantages. First, fiber optics significantly reduce signal loss over long distances, making them ideal for transporting test signals to safety distances exceeding 400 feet. Additionally, fiber optics are immune to electromagnetic interference (EMI), ensuring superior signal integrity in high-noise, high radiated RF power environments commonly encountered during EMC tests. Their lightweight and compact nature facilitates easier handling and installation in the confined spaces of aircraft for various test setups. Furthermore, the inherent isolation of optical fibers, as they do not conduct electricity, eliminates the risk to test equipment and personnel from high fields and in tests involving lightning simulation. Lastly, RF over Fiber systems offer greater flexibility and scalability, allowing engineers to extend the frequency and test configurations to accommodate a variety of requirements without compromising performance. These attributes collectively make RF over Fiber a more effective choice for critical EMC testing applications in the aerospace industry.

WHY RFoF INSTEAD OF COAX FOR EMC MEASUREMENTS?

Using RF over Fiber instead of coaxial cables for EMC testing in aircraft development presents several technical advantages. First, fiber optics significantly reduce signal loss over long distances, making them ideal for measurements exceeding 400 feet. Additionally, fiber optics are immune to electromagnetic interference (EMI), ensuring superior signal integrity in high-noise environments commonly encountered during EMC tests. Their lightweight and compact nature facilitates easier handling and installation in the confined spaces of aircraft testing setups. Furthermore, the inherent safety of fiber optics, as they do not conduct electricity, minimizes the risk of electrical hazards, an essential consideration in aircraft where lightning and electrical issues are concerns. Lastly, RF over Fiber systems offer greater flexibility and scalability, allowing engineers to adapt their testing configurations to varying requirements without compromising performance. These attributes collectively make RF over Fiber a more effective choice for critical EMC testing applications in the aerospace industry.

KEY CHARACTERISTICS FOR EMC MEASUREMENTS

The testing setup comprises a 19-inch removable rack housed in a van, which contains the necessary equipment for transmitting (Tx) and receiving (Rx) signals up to 18 GHz. Inside the aircraft, a dedicated enclosure is equipped with a rechargeable battery, providing power to the system during EMC field measurements. The RF connector from this enclosure is connected to a detector specifically designed to measure electromagnetic fields. Connecting the van and the aircraft is a robust optical cable, which is conveniently rolled onto a trolley for easy deployment and management. This arrangement ensures efficient data transmission while maintaining the integrity of the signals being tested, creating an effective and mobile EMC testing solution in aircraft development.

FREQUENCY RANGE & RF COVERAGE

The solution primarily employs a 0.1 to 18 GHz RF over Fiber link, equipped with amplifiers to ensure optimal signal strength and performance across the frequency range. This setup is designed to provide reliable measurements during EMC testing, facilitating accurate detection of electromagnetic fields. In certain cases, a 1 to 40 GHz link may also be utilized, offering additional bandwidth and flexibility for specific testing requirements. This modularity allows engineers to adapt the system based on the particular electromagnetic spectrum of interest, enhancing the overall effectiveness of the EMC testing process in aircraft development.

APPLICATION & SYSTEM ARCHITECTURE

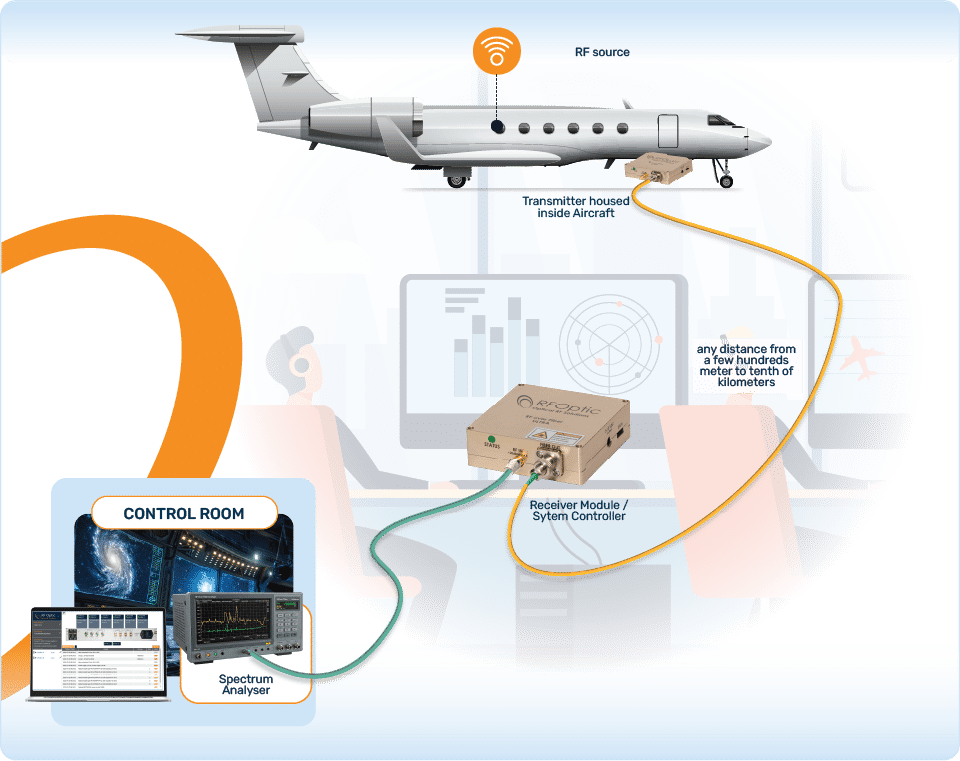

The system has two parts linked by a optical fiber cable. The test equipment part is in a van or a shelter and includes a hot-swappable module rack that houses a transmit and receive converters capable of operating primarily within the 0.1 to 18 GHz frequency range. A set of additional RFoF converters is available to extend the test capability up to 40 GHz when needed. The aircraft part of the setup features a compact enclosure with a rechargeable battery to power the RF components during tests. This approach isolates the sensor part from the aircraft. It ensures mobility and convenience in locating the sample point in and around the aircraft. The RF converter interfaces directly to a detector that measures the induced fields, while a robust optical cable, rolled on a trolley, links the van and the aircraft part of the setup. This design facilitates easy setup, maintenance, and adjustments to accommodate varying testing scenarios, making it an ideal solution for comprehensive EMC assessment in the aviation industry.

SYSTEM CONFIGURATION EXAMPLE

The RF over Fiber system designed for aircraft EMC testing is a sophisticated setup that facilitates the precise measurement of electromagnetic fields in a controlled and efficient manner. The system components consist of a mobile van housing a 19-inch removable rack equipped with essential transmission (Tx) and reception (Rx) units. These units operate predominantly in the 0.1 to 18 GHz frequency range, with the capability to extend up to 40 GHz for specialized testing applications.

Inside the aircraft, a compact enclosure is integrated to house a rechargeable battery, which powers the RF components throughout the testing process. This design ensures that the system remains mobile and can be operated without reliance on external power sources, enhancing its versatility in various test environments. The RF connector from this enclosure is directly linked to an advanced detector responsible for capturing and analyzing electromagnetic fields, allowing for real-time data collection and monitoring.

A key feature of the system is the optical cable that connects the van and the aircraft. This cable, which is rolled on a convenient trolley, ensures flexible and organized deployment of the system while maintaining signal integrity over long distances. The use of fiber optics mitigates signal loss and electromagnetic interference, resulting in more accurate measurements during EMC testing.

Additionally, the RF over Fiber system is designed with user-friendly controls and interfaces, enabling engineers to easily configure and monitor test parameters. Its modular structure allows for quick adjustments and scalability, accommodating various testing scenarios and ensuring compliance with regulatory standards. This comprehensive system not only enhances the safety of aircraft development by identifying potential EMC issues but also streamlines the testing process, making it an invaluable tool in the aerospace industry.

REMOTE MONITORING AND CONTROL (M&C)

RFOptic’s multilink products and subsystems may include a remote Management and Control (M&C) option. These products can be managed and controlled over Internet Protocol (IP). They offer a webserver interface that allows graphical monitoring and control of the system. Furthermore the M&C system supports REST protocol as well as SNMP V2c interfaces both with extensively documented Application Programming Interface (API) that enable customers to integrate into existing automatic test procedures.

DEPLOYMENT

1U Removable 19-Inch Rack in the Van: The RF over Fiber system features a 1U removable 19-inch rack housed in a van, which serves as the core operational unit for EMC testing. This rack is equipped with essential components, including a spectrum analyzer and RF source, enabling real-time signal transmission and analysis. The design allows for easy access to the equipment, facilitating quick adjustments and troubleshooting as needed during testing. The mobile nature of the van ensures that the system can be transported to various testing locations while maintaining the necessary functionality and performance required for accurate measurements.

Compact Box with Rechargeable Battery in the Aircraft: On the aircraft side, the system is connected through a robust optical cable to a compact box designed for mobility and efficiency. This enclosure is equipped with a rechargeable battery that provides a reliable power source, allowing the system to operate independently within the aircraft. Its compact design enables easy placement in various locations, accommodating the spatial constraints of the testing environment. This setup is critical for measuring electromagnetic fields effectively, ensuring that engineers have the flexibility to conduct tests without being tethered to external power sources. The combination of the compact box and optical coupling enhances the overall mobility of the RF over Fiber system during aircraft EMC testing.

CONCLUSION

The RF over Fiber system provides a robust solution for EMC testing in aircraft development. Its design enhances measurement accuracy by minimizing signal loss and eliminating electromagnetic interference. The mobile setup features a 1U removable rack in the van, while the compact rechargeable battery box in the aircraft contains an RF over Fiber transmitter, ensuring complete functionality in a confined space. This configuration allows for flexibility and independence, facilitating testing in various environments. Additionally, the user-friendly design streamlines operations, enabling quick adjustments and seamless monitoring. Overall, this system effectively meets the demanding requirements of EMC testing and highlights the increasing need for reliable RF over Fiber technology in the aerospace industry, making it an ideal choice for engineers seeking effective and efficient testing solutions.

Contact Us